Special Purpose Machines (SPMs) are customized machines designed to perform specific tasks or operations, tailored to the unique requirements of a particular manufacturing process or industry. SPMs are often built for tasks that cannot be easily accomplished using standard off-the-shelf machines. Specialization in the field of Special Purpose Machines involves focusing on designing, engineering, and manufacturing these machines for specific applications and industries. Here's an elaboration on specialization in this field:

Industry Focus:

Specialization often begins with a focus on a specific industry or set of related industries, such as automotive, aerospace, electronics, packaging, pharmaceuticals, or any other sector that requires specialized machinery for their manufacturing processes. Understanding the unique needs and intricacies of a particular industry helps in developing highly efficient and effective SPMs.

In-Depth Understanding of Processes:

Specialists in SPMs gain a deep understanding of the manufacturing processes within their chosen industry. They analyze the workflow, identify bottlenecks, and pinpoint areas where automation and specialized machines can significantly improve efficiency, precision, speed, or safety.

Customized Solutions:

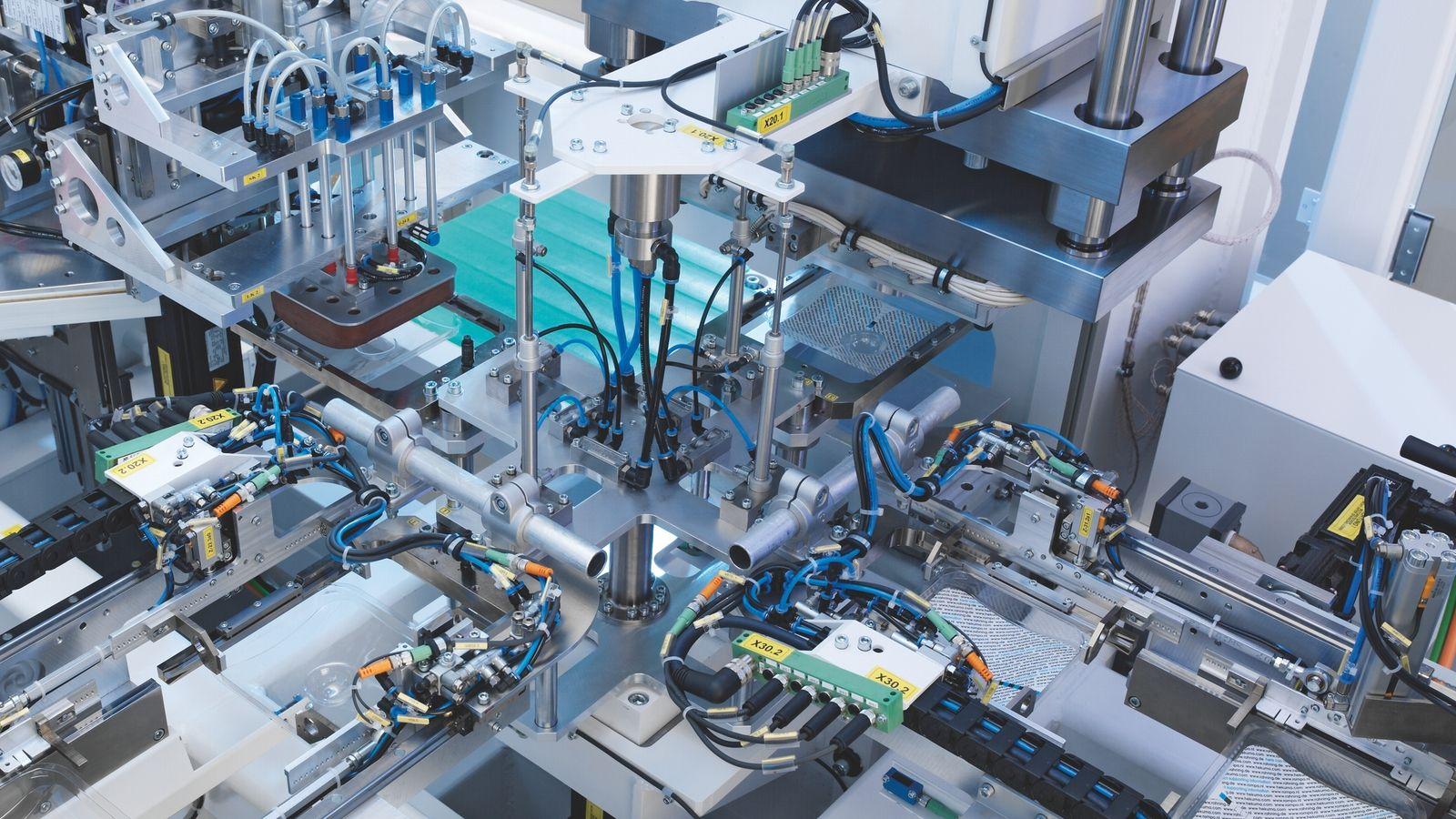

Specialization involves the ability to provide tailored and customized solutions. Engineers work closely with clients to understand their specific requirements, challenges, and goals. They design and build SPMs that precisely address these needs, ensuring the machines integrate seamlessly into the existing manufacturing setup.

Expertise in Automation and Robotics:

Automation is a key aspect of specialization in SPMs. Specialists possess expertise in automation technologies, robotics, control systems, and software integration. They design machines that can automate complex and repetitive tasks, enhancing productivity and accuracy.

Innovative Design and Engineering:

Specialized SPM providers are often at the forefront of innovation, developing novel designs and engineering solutions. They constantly research and experiment with new technologies to improve the performance, reliability, and versatility of their machines. Innovation may involve advanced materials, sensors, IoT integration, or other emerging technologies.

Efficiency Optimization:

Specialists in SPMs focus on optimizing the efficiency of manufacturing processes. This includes reducing cycle times, minimizing waste, maximizing throughput, and enhancing resource utilization. Efficiency gains lead to cost savings and improved competitiveness for the businesses using these specialized machines.

Compliance and Quality Assurance:

Ensuring that the specialized machines comply with industry standards, safety regulations, and quality requirements is a critical aspect of specialization. Providers need to have a thorough understanding of relevant standards to design and manufacture machines that meet or exceed these criteria.

Technical Support and Maintenance:

Specialization involves providing ongoing technical support, maintenance, and upgrades for the SPMs. This ensures the machines continue to operate at peak performance levels throughout their lifecycle, supporting the client's production needs effectively.