Get In Touch

TESTING SOLUTIONS

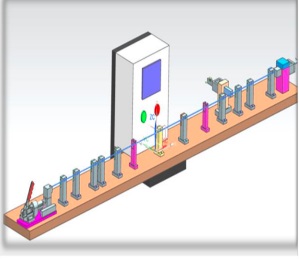

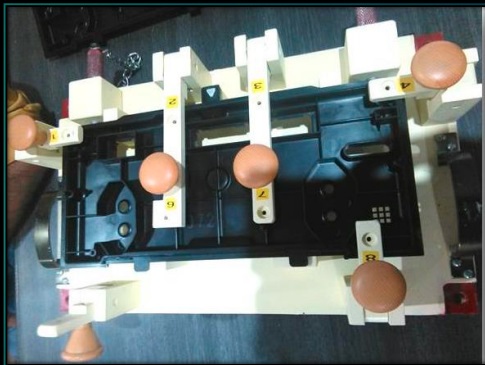

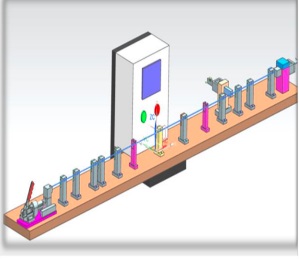

We provide different types of testing solutions. Mechanical testing machine automation involves the integration of automated systems and software to control, monitor, and analyze the testing processes performed by mechanical testing machines. These machines are used to evaluate the mechanical properties and behaviors of materials, components, or products. Automating these processes improves efficiency, accuracy, and repeatability of the tests.

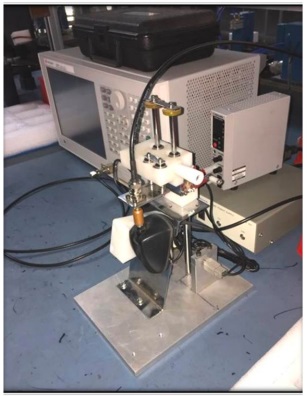

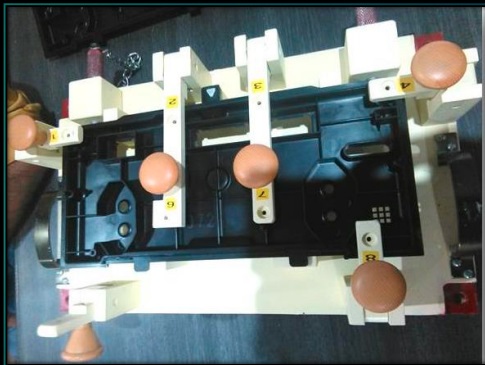

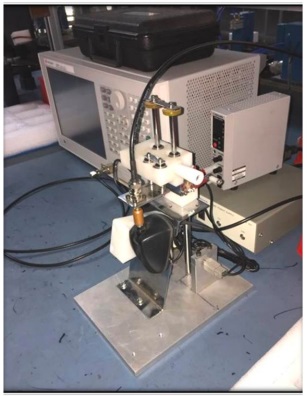

Integration with Sensors and Actuators:

Integrate sensors and actuators into the testing machine to measure parameters like force, displacement, strain, and control the machine's movement.

Automated Control System:

Implement an automated control system using software and hardware that can control the testing machine, set testing parameters, and collect data during tests.

Applications:

Software Development:

Develop software to control the testing machine, allowing for automated execution of testing procedures, parameter adjustments, and data collection.

User Interface (UI):

Design a user-friendly interface that enables operators to input test parameters, start tests, and view real-time data and

results.

Data Acquisition and Analysis:

Incorporate features for data acquisition and analysis within the software to process and interpret data collected during tests, generating comprehensive reports.

Calibration and Validation:

Ensure the accuracy and reliability of the automated system by calibrating and validating the testing machine and its components.

Safety Features:

Implement safety mechanisms to ensure the safe operation of the testing machine and protect operators during testing.

Training and Support:

Provide training to operators and maintenance personnel on how to use and maintain the automated testing system effectively.

Maintenance and Upgrades:

Establish a maintenance schedule and a plan for regular updates and improvements to keep the automated system functioning optimally.

Automating mechanical testing machines enhances productivity, accuracy, and consistency in testing procedures, making it an essential aspect of modern material and product testing processes. It also allows for more extensive data analysis and interpretation, aiding in research and development efforts.