Get In Touch

MACHINE VISION SOLUTIONS

We provide different types of machine vision solutions commonly used in automation:

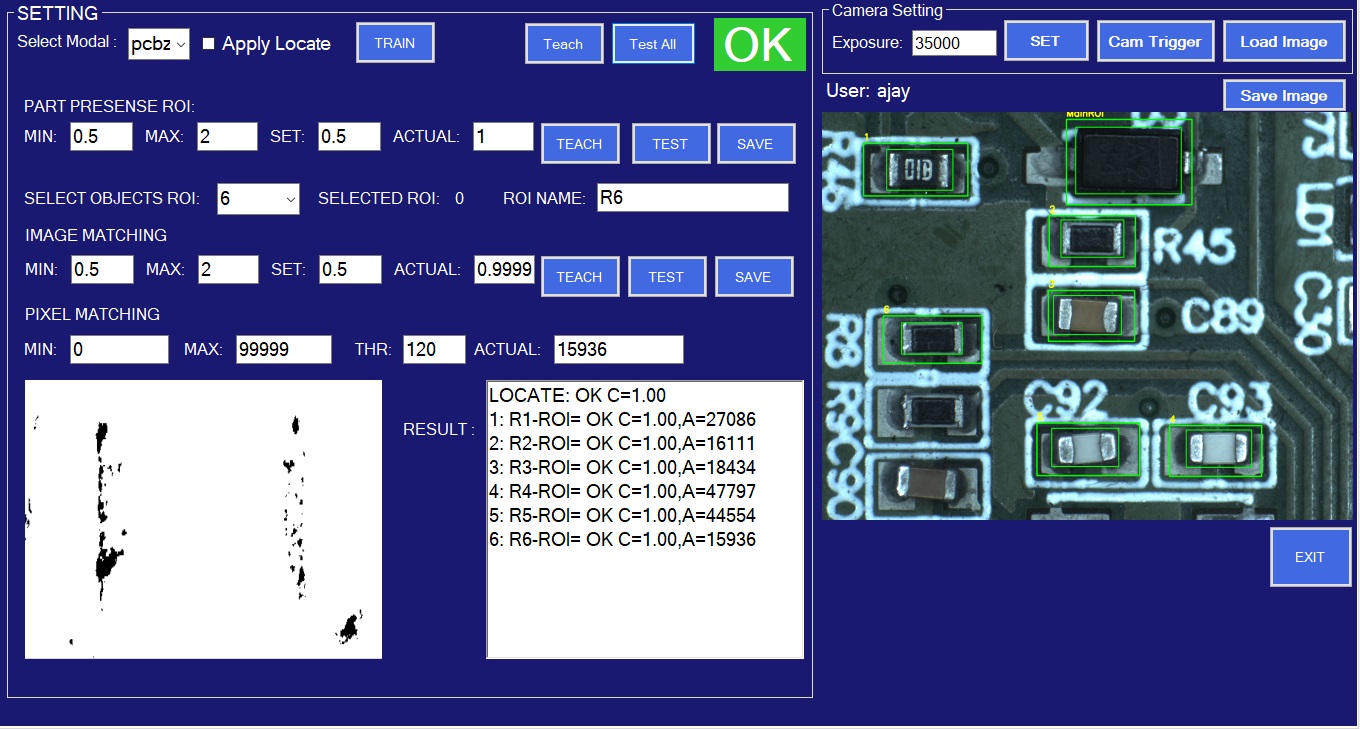

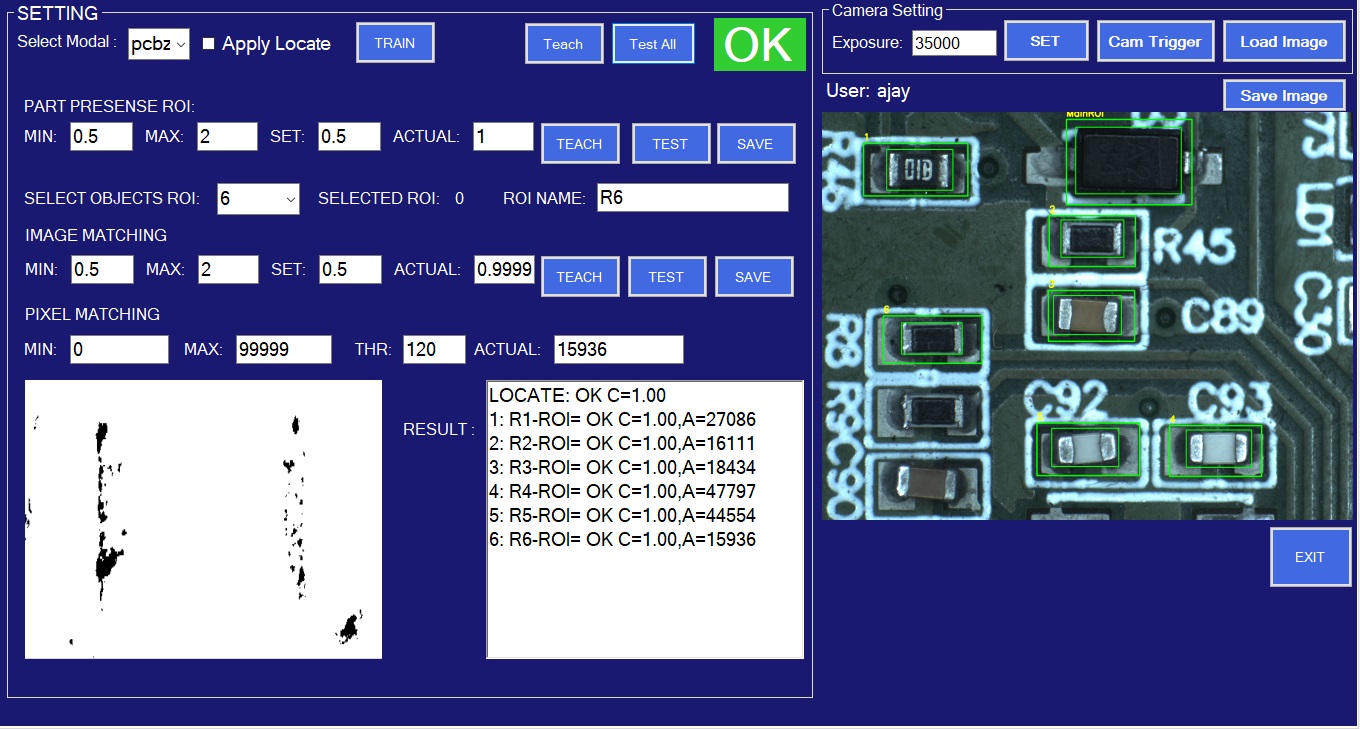

2D Vision:

2D vision involves analyzing images captured in two dimensions (height and width). It's commonly used for applications such as object recognition, positioning, barcode reading, and optical character recognition (OCR).

Applications:

Automated inspection and quality control on assembly lines.

Sorting and identifying products based on labels or markings

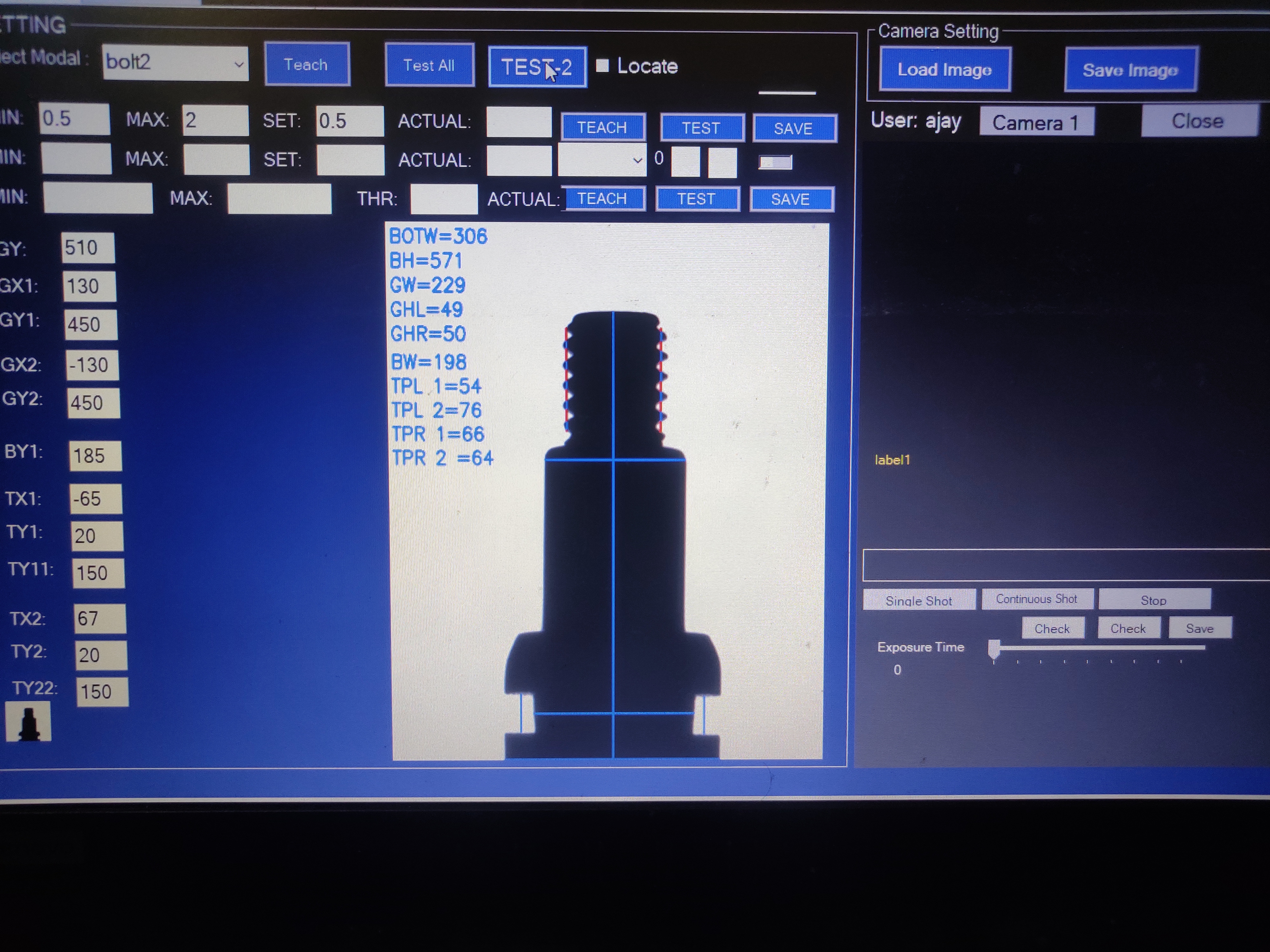

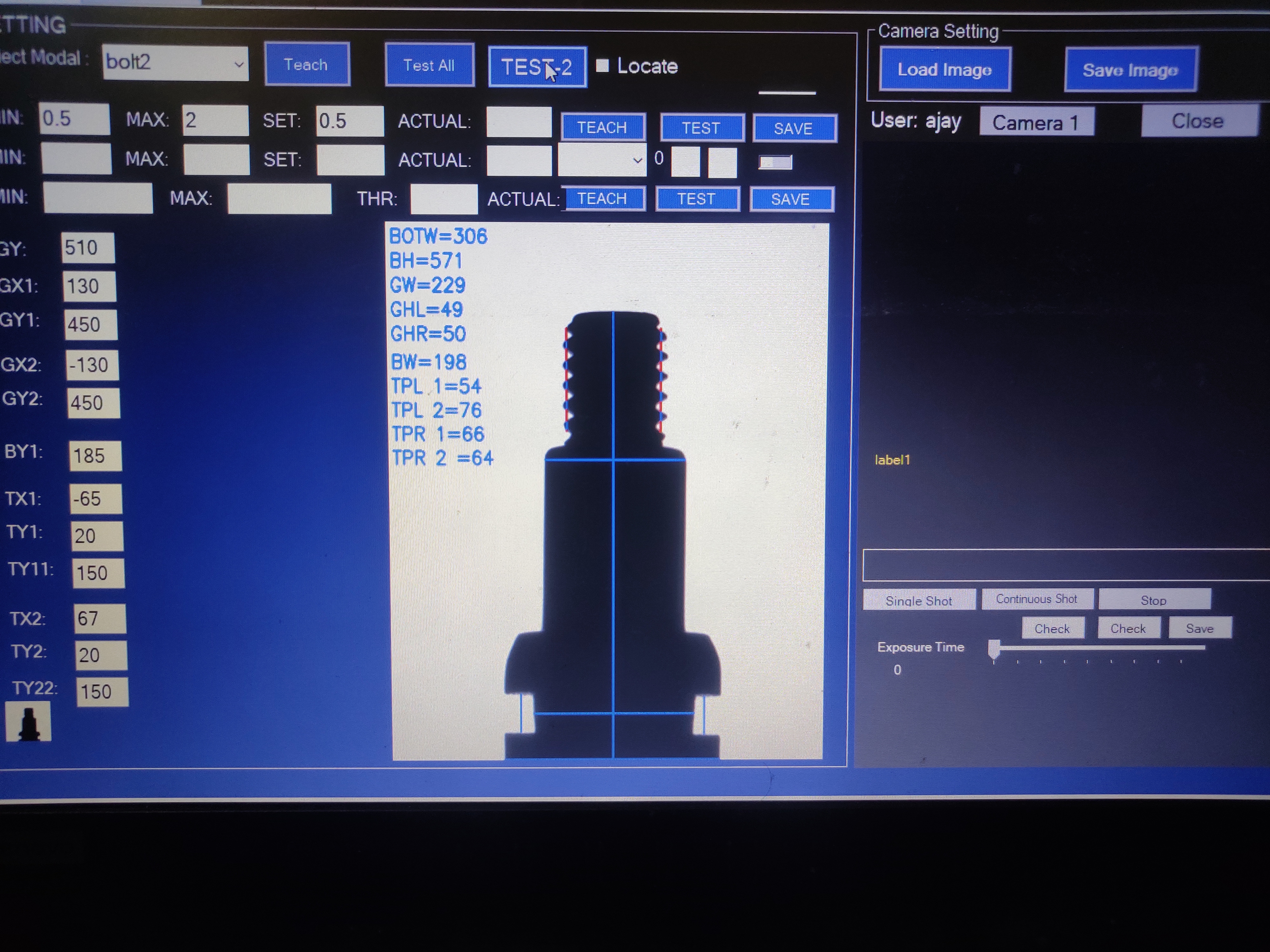

Surface Inspection:

Surface inspection involves examining the surface characteristics of objects or materials to detect defects, imperfections, or inconsistencies.

Applications:

Quality control in manufacturing to detect surface defects in materials like glass, metal, or plastics.

Pattern Recognition:

Pattern recognition involves identifying specific patterns or features within an image, allowing machines to recognize and classify objects based on predefined patterns.

Applications:

Identifying specific parts or components in assembly processes.

Sorting items based on patterns or shapes.

Object Detection and Localization:

Object detection involves identifying and locating specific objects within an image or video stream. It's used for automation and robotics to guide actions based on detected objects.

Applications:

Robotics for automated pick-and-place tasks in warehouses and manufacturing.

Automated guided vehicles (AGVs) for navigation and obstacle avoidance.

Color Vision:

Color vision involves analyzing the colors within images to differentiate and classify objects based on color properties.

Applications:

Sorting products based on color in manufacturing and logistics.

Detecting color-based defects in products.

Motion Analysis:

Motion analysis involves tracking and analyzing the movement of objects within an image or video, providing valuable information for automation and control systems.

Applications:

Monitoring and optimizing conveyor belt speed and product flow.

Analyzing human movements for applications like gesture control.